Understanding Oxy Gas Welding Kits

What is an Oxy Gas Welding Kit?

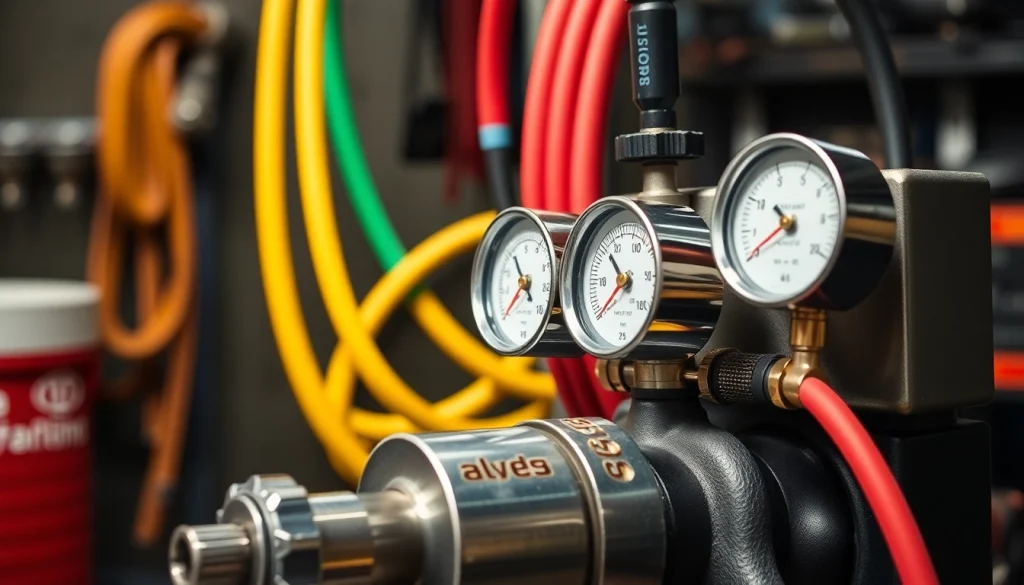

An oxy gas welding kit is an essential toolkit used for welding and cutting metal materials through the application of heat produced by the combustion of oxygen and acetylene gases. Typically, these kits include a torch, gas cylinders (a tank for oxygen and a tank for acetylene), hoses, and a set of regulators that help control the flow of gases. This combination allows for precise temperature control, making it possible to effectively melt metal for welding, cutting, or brazing operations. Oxy gas welding is widely utilized in various industries due to its versatility and effectiveness in joining metals of different compositions and thicknesses.

Common Applications of Oxy Gas Welding Kits

Oxy gas welding kits find their applications across a broad spectrum of industries and projects. Key applications include:

- Metal Fabrication: These kits are indispensable in metalworking shops, where they are used for fabricating metal structures, custom artwork, and specialized tools.

- Automotive Repair: In automotive settings, oxy gas welding is vital for repairing frames, exhaust systems, and other metal components.

- Construction: Construction workers employ oxy gas welding kits for tasks such as steel beam installation, sheet metal work, and piping.

- Maintenance and Repair: Many technicians use these kits to perform maintenance on machinery, piping, and equipment that require welding or cutting repairs.

- Artisans and Hobbyists: Artists and hobbyists appreciate the control and craftsmanship achievable through oxy gas welding for projects varying from sculptures to home décor.

The Importance of Quality in Welding Tools

Quality plays a crucial role in the effectiveness and safety of oxy gas welding kits. High-quality components ensure better performance, increased reliability, and improved results. Inferior equipment can lead to inconsistent results, increased downtime due to breakdowns, and can posing serious safety risks. Thus, investing in reputable brands known for their durability and effectiveness is essential for both professionals and amateurs alike.

Choosing the Right Oxy Gas Welding Kit

Key Components to Consider

When selecting an oxy gas welding kit, critical components should be taken into consideration to ensure the right fit for your needs. These components include:

- Gas Cylinders: Choose cylinders based on the project scale. Standard tank sizes for acetylene are MC, B, and M, which correspond to varying volumes needed for different applications.

- Welding Torch: The torch must allow for good control of the flame. Consider multi-tip torches for versatility in different welding tasks.

- Regulators: High-quality regulators are vital as they control the pressure of the gas fed into the torch. Look for dual-stage regulators for stable pressure control.

- Hoses: Ensure hoses are made of durable materials resistant to cuts and abrasions. The presence of a color-coded setup helps identify oxygen and acetylene cylinders easily.

- Safety Equipment: Include safety goggles, gloves, and protective clothing to ensure personal safety. Flame arrestors and check valves in the hoses can prevent backfire.

Evaluating Kit Features and Specifications

Not all welding kits are created equal, and features often vary significantly between products. When comparing options, consider the following technical specifications:

- Flame Temperature: Acetylene burns at a maximum temperature of about 3,200°C, making it suitable for most welding and cutting tasks.

- Tip Size Options: Multiple sizes allow for a variety of welding tasks, effectively managing heat input and ensuring precise control during operations.

- Weight: Lighter kits are preferable for mobile applications or when portability is needed, while heavier setups may be more stable in fixed locations.

- Warranty and Service Options: Quality kits typically come with extended warranties, which can be a crucial factor in making a purchasing decision.

Comparing Brands and Prices

The market offers an array of brands and price points for oxy gas welding kits. While it might be tempting to choose a lower-priced kit, be cautious: the highest quality tools are often the most reliable and safest options. Consider brands like Harris, Victor, and Unimig, known for their superior products. Compare costs but factor in warranty, customer reviews, and availability of replacement parts, as these can save money and headaches down the line.

Setting Up Your Oxy Gas Welding Kit

Safety Precautions Before Use

Safety is paramount when working with oxy gas welding kits. Here are some vital precautions:

- Always operate in a well-ventilated area to avoid the buildup of toxic gases.

- Check for gas leaks using soapy water to identify any spots before starting your work.

- Use flame arrestors and ensure all hoses are intact and properly connected.

- Wear appropriate personal protective equipment, including goggles, gloves, and heat-resistant clothing.

- Store gas cylinders upright and secured to prevent falling, and keep them away from flammable materials.

Step-by-Step Setup Instructions

Setting up your oxy gas welding kit requires careful attention to detail. Follow these steps:

- Gather Tools and Equipment: Ensure all components of your kit are available and in good working condition.

- Prepare the Work Area: Clear any combustibles and ensure adequate ventilation in the workspace.

- Connect Regulators: Attach the regulators to the gas cylinders, ensuring they are secured tightly with no leaks.

- Assemble Hoses: Connect the hoses from the regulators to the torch, ensuring they are connected to the correct ports—red for acetylene and green for oxygen.

- Attach Torch Nozzle: Verify that the appropriate nozzle is attached to the torch for the task you are performing.

- Open Gas Cylinders: Slowly open each gas cylinder valve and adjust the pressure to the desired settings.

- Ignite the Torch: Use a flint spark lighter to ignite the gas at the torch tip while first adjusting the acetylene, followed by the oxygen to achieve the desired flame.

Common Setup Mistakes to Avoid

Even experienced welders can make mistakes during setup that may cause hazards or ineffective welding. Here are some pitfalls to avoid:

- Neglecting to check for gas leaks before ignition can lead to dangerous situations. Always perform a bubble test.

- Incorrectly connecting hoses or regulators can result in backfire or burn-through situations during operation.

- Using outdated equipment that does not conform to safety standards may result in severe accidents. Regularly inspect and replace as necessary.

- Failing to follow the proper ignition sequence can lead to a sudden flare-up, causing potential harm.

Techniques for Using Your Oxy Gas Welding Kit

Basic Welding Techniques for Beginners

For beginners, mastering basic welding techniques is crucial for building competence and confidence. Here are some essential techniques:

- Stringer Bead: This is a straightforward technique for beginners. Move the torch steadily along a joint to create a thin molten bead.

- Weaving Technique: This involves moving the torch back and forth across the joint, which can help in joining larger gaps or thicker materials.

- Puddle Control: Beginners should focus on maintaining the correct puddle size for the material being welded. A larger puddle is forgiving, while a smaller puddle requires more precision.

Advanced Techniques for Professional Results

As skills improve, so can welding techniques. Professionals often utilize advanced techniques for more complex projects:

- TIG Welding: While not strictly oxy-fuel, incorporating Tungsten Inert Gas (TIG) welding principles into oxy acetylene work can produce cleaner, high-quality welds.

- Bronze Welding: This technique allows for welding dissimilar metals, using bronzes or special filler rods.

- Sections Welding: Advanced welders can manipulate the torch angle and height above the workpiece to achieve different penetration depths and bead sizes.

Maintaining the Perfect Flame

Achieving and maintaining the perfect flame is crucial for successful oxy gas welding. The flame type can be adjusted to suit various applications:

- Neutral Flame: Ideal for most welding tasks, neutral flames consist of a balanced mixture of oxygen and acetylene, creating a clean, hot flame.

- Carburizing Flame: This flame is richer in acetylene and is used for welding cast iron and other metals sensitive to oxidation.

- Oxidizing Flame: An oxidizing flame has more oxygen, which can be used for cutting but is not recommended for welding due to the potential for oxidation.

- Regularly adjust and test your flame to ensure the right settings before every welding task.

Common Issues and Troubleshooting

Troubleshooting Common Problems with Oxy Gas Welding

Even seasoned professionals encounter issues while welding. Some common problems include:

- Backfire: If the flame goes out with a sound, check for gas leaks and ensure the torch tip is not obstructed.

- Weak Flame: This may indicate a blockage in the hoses or tip; check and clean accordingly.

- Puddle Too Hot or Cold: Adjust the fuel mix and heat settings to control the temperature and melting point effectively.

When to Seek Professional Assistance

While many issues can be resolved independently, certain situations warrant professional help:

- Persistent gas leaks, which can pose safety hazards, should be addressed by an experienced technician.

- If you experience recurring equipment failures, it may indicate underlying issues requiring specialized skills for diagnosis and repair.

- Complex welding projects that put unique strains or demands on your equipment, necessitate expert advice to ensure safety and quality work.

Resources for Continuous Learning and Improvement

Welding is both an art and a science, and continuous education is vital for improvement. Resources include:

- Online Courses: Websites like Udemy and Coursera offer courses specialized in welding techniques.

- Local Trade Schools: Many community colleges offer hands-on training and certification programs.

- Welding Forums: Engaging in discussions on platforms like Reddit or specialized welding forums can provide valuable tips and insights from peers.

- Books and Manuals: Invest in comprehensive guidebooks that cover both the fundamentals and advanced techniques.